The Final Brush Sander is the definition of reliability. Designed for the sanding preparation of raw and undercoated material ready for final coating, this machine is like having a team of skilled sanders at the ready.

The Final will sand your material consistently and quickly, removing the vast majority of manual input. This machine will free up your time and significantly save you on labour delivering predictable results each time.

Key Features

– Multiple configurations available

– Incredible efficient

Standard Equipment

- Fixed table h=900 mm

- Height adjustable work units

- NC machine control color Touchscreen 10.1″ B & R – automatic movement of the table to the specified position – control of the working positions of individual aggregates – the possibility of saving different configurations of machine settings in 40 programs – display of the load on the main motors – counter of operating hours of individual aggregates – error messages with graphic by display – the possibility of adding remote diagnostics of the VPN machine – language localization

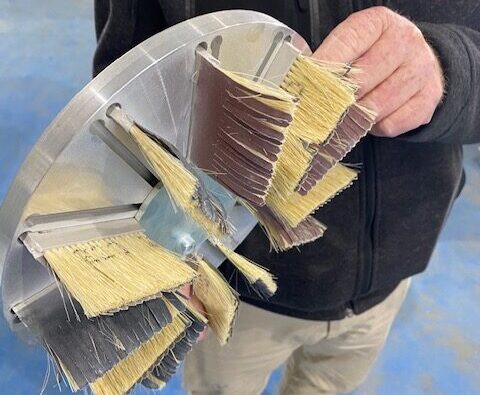

- Pull-out unit D – disc rotation unit located in 2 rows with oscillation (only for DB, DBB, DDBB version)

- Disc diameter 250 mm, width 1350 mm – 11 discs (only for DB, DBB, DDBB version)

- 24 grooves on the disc – 12 pairs each , groove length 70 mm (only for DB, DBB, DDBB version)

- Smooth regulation of the rotation speed of the discs – range 50 – 300 rpm. (only for DB, DBB, DDBB version)

- Manual adjustment of the oscillation range – range 20, 40, 60, 80, 100 mm (only for DB, DBB, DDBB version)

- Disk drive oscillation frequency converter 20-60 rpm. (only for DB, DBB, DDBB version)

- Brush height 20-100 mm with workpiece thickness 100 mm (only for DB, DBB, DDBB version)

- Reverse operation of disk drive D (only for version DB, DBB, DDBB)

- Units B – cylindrical brushing units with oscillation

- Shaft speed of unit B 1000 rpm.

- Pressure rollers

- Motorized lift of the grinding unit – workpiece height 3-100 mm

- Automatic star/delta switching

- Frequency converter of the speed of the feeding belt 3-15 m/min

- Automatic centering of the feed belt

- Digital measurement of brush position

- Optoelectronic brush calibration sensor

- Glass side door

- Cylindrical brush shaft diameter 60 mm

- Min./max. diameter of the cylindrical brush 150-300 mm

- Voltage 400V/50Hz

- The machine is manufactured in accordance with CE standards

‘Our new Houfek denibbing and sanding machine is unique, and it will lessen our workload and maintain consistency of our product’

Optional Equipment

Motors/frequency converters

• Motor 3 kW (4 HP) – for unit D (only for version DB, DBB, DDBB)

• 5.5 kW (7.5 HP) motor – for unit B

• 7.5 kW (10 HP) motor – for unit B

• Frequency converter for disk rotation speed – range 50-600 rpm. (only for DB, DBB, DDBB version)

• Frequency converter unit B, 50-300 rpm

• Frequency converter unit B, 180-1000 rpm.

• Unit B frequency converter , 7.5 kW, 50-300 rpm

• Frequency converter unit B 7.5 kW, 180-1000 rpm

• Reverse operation of unit B

Side brushing units

Side brushing units K2 E

• Horizontally adjustable – electronically with measuring

• Vertically adjustable – manually

• Rotating diameter of the tool 2 x 150-300 mm

• Working height of the tool 150 mm

• Minimum width of the workpiece 50 mm

Unit B

• Setting one working unit B at an angle- rotation angle 10°

Unit D

• Disc D=250 mm/24 slots for unit D – 1 pc (only for DB, DBB, DDBB version)

– width 1100 mm – 9 discs

Cleaning units

• Feeding belt cleaning module with-

– motor power – 1.5 kW (2 HP)

– work tool D=100 mm

– cleaning roller – horsehair

– on the bottom side of the table outlet – suction outlet D=180 mm

• Cleaning of work pieces with an oscillating blower- switching when the work piece passes through

• Ionization rod at the output of the machine

Other

• Additional table 300 mm – entrance

• Additional table 300 mm – output

• Maximum workpiece height 160 mm

• Vacuum table

• Vacuum cleaner with silencer – in the machine

• Pneumatically controlled suction flap D=180 mm

• Internal LED lighting of the machine

• VPN remote machine diagnostics

Machine Specifications

Possible configurations: aggregates DB, DBB, DDBB, BB, BBB, BBBB