Wide belt sanders are excellent machines for sanding large pieces of wood or metal, however,

deciding which unit is right for you can be complex with all the different brands and

configurations. We provide five helpful tips to help you find the best wide belt sander. These tips ensure you get

what you need, from budget to extraction So, let’s get started!

1. Consider Your Budget

A wide belt sander is a long-term investment. Creating and following a budget before

purchasing any production machine is an excellent way to be sure you get the best sander for

what you can afford. Before shopping around, it is worth considering that a cheaper machine

may have a lower initial investment but could end up costing more in repairs and abrasives in

the long term. Machines with a higher-quality build that use high-end components are more

likely to provide longevity and be more reliable. Consider the return on investment that a reliable

and accurate wide belt sander can provide in the long term.

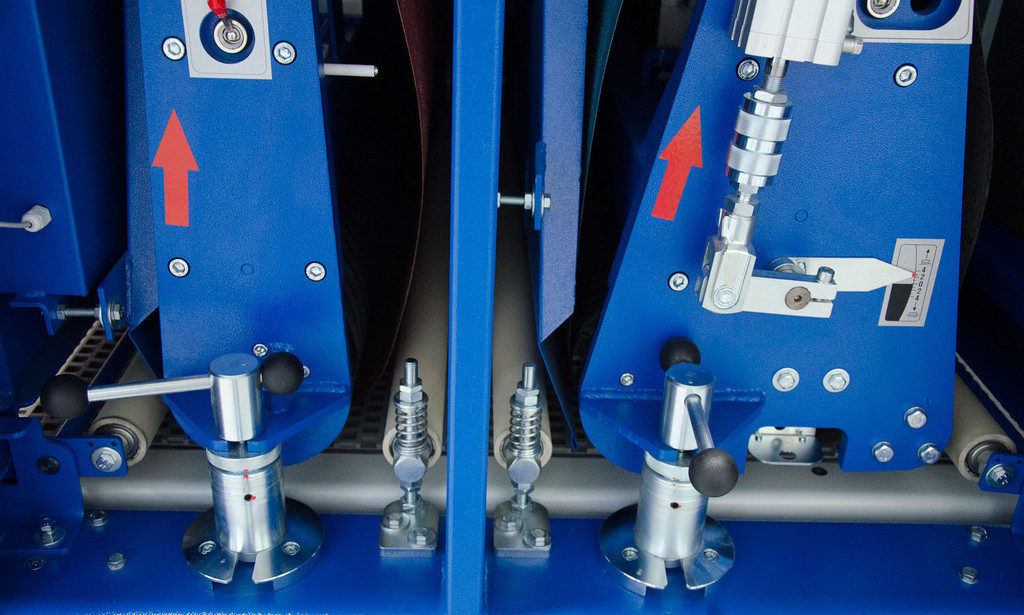

2. Consider the Machine’s Structure and Components

The machine’s outside paint and brand may look very attractive, but what’s lurking underneath

may not be.

Different countries have different safety and quality requirements when it comes to machinery

manufacturing compliance. Some brands outsource some of their manufacturing to cheaper,

less stringent manufacturers in other countries, so find out where the machine you are

considering is made. The machine frame should be made from heavy-duty steel that can

withstand repetitive motion and vibration without buckling or deforming. The overall structure

should be rigid, with no weak points or potential areas of breakage. The components should be

of high quality to maximise longevity- they can be expensive to replace! Also check for how

many motors the machine has. A wide belt sander should have one motor per contact roller/unit.

Machines that only have one motor driving two units can lose traction and cause slippage of the

contact roller onto the workpieces. This causes a poor finish and damage to the vee belt and the

workpiece.

3. Decide on the right configuration

Wide belt sanders come in all shapes and configurations so it is important to consider a

machine that not only suits you now but can see you in the future. If you are used to using a

900mm wide machine, a wider machine with a different configuration could allow you to take on

more work or different kinds of work. In terms of configuration, you can select a pad and roller,

calibrating roller only, spiral cutter block and the list goes on. Don’t just buy what a vendor might

have in stock, it is important to speak to someone who understands the sanding process really

well and can assist you with selecting a suitable machine to amplify your production.

4. Look at the Optional Features

One of the most important factors to consider when looking for a high-quality wide belt sander is

the list of standard and optional features. Optional features customise your sander to suit your

specific sanding jobs and can take your woodworking or metalworking project to the next level.

We highly recommend a few optional features to amplify a machine’s sanding capabilities.

● Correct Contact Roller- your machine needs to have the right contact roller for your

sanding jobs. For example, if you are calibrating table tops with glue lines or Australian

hardwood, you would need a steel contact roller as your first unit.

● Air Cleaning Devices- these cleaning devices significantly extend the life of the sanding

abrasives.

5. Evaluate your Dust Extraction needs

Dust extraction is essential for keeping your workspace clean and debris-free while sanding. It

extends the life of the machine and also the abrasives. If your premises doesn’t already have

extraction, it is worth checking the recommended extraction rating for the wide belt sander you

are considering and also consider the other machines in your production.

The dust extractor should be designed to capture the maximum amount of debris without

clogging or becoming obstructed due to buildup. It should also have easy access for

maintenance and cleaning so that you can ensure the best performance. Additionally, the dust

collector should be designed to work with the sander’s specific model and sized to fit

appropriately and operate optimally.

Conclusion

Before you make this long term investment, it is really important to speak to a sanding specialist

who has a good understanding of the sanding process and the materials to be processed.

Really understanding the features of a sander can mean the difference between purchasing a

good sander and a great sander.

Are you searching for a high-quality wide-belt sander?

Check out the European made Houfek range of Wide belt sanders with Reliance Machinery! We can help you select an accurate,

reliable and robust sander that suits your needs for now and into the future, whether you’re a startup, a non-profit, or a government agency. Contact us today for more information!.