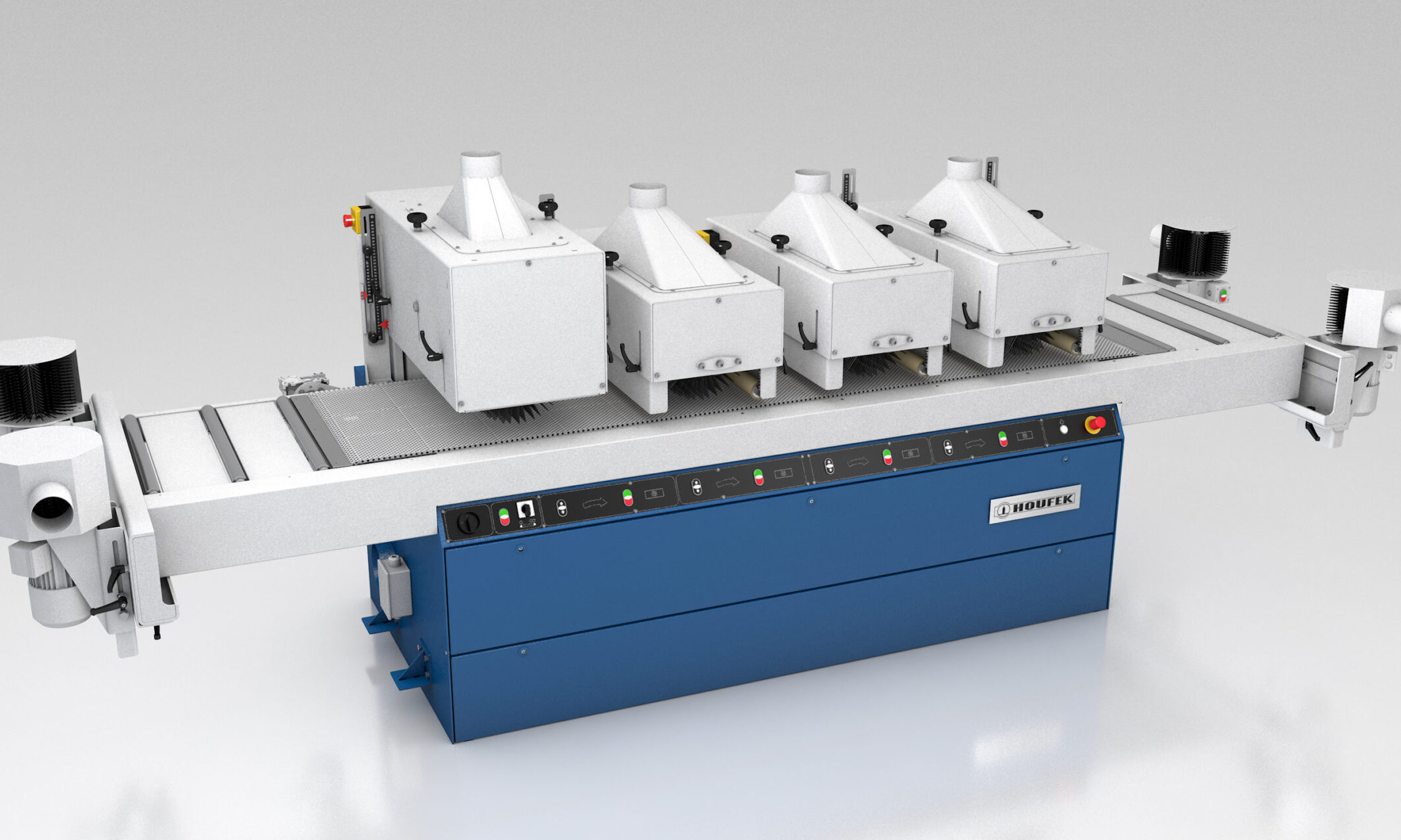

The Twingo is a cost effective, space saving solution for those who need to process raw and undercoated products. This machine is ideal for shaker style doors, moldings and molded panels. The brushes follow contours into moldings and profiles that a flat sander simply cannot reach. This removes a huge amount of the manual labour that would otherwise have to be done by hand with soft sanding pads. Available in 600mm and 400mm widths in varying configurations, if you are looking for a shaker door sanding machine- look no further!

Designed for sanding and brushing works for raw and undercoated products.

Key Features

open style design means larger pieces can be processed. For example, a 600mm wide machine can process a 1200mm wide panel via two passes

Standard Equipment

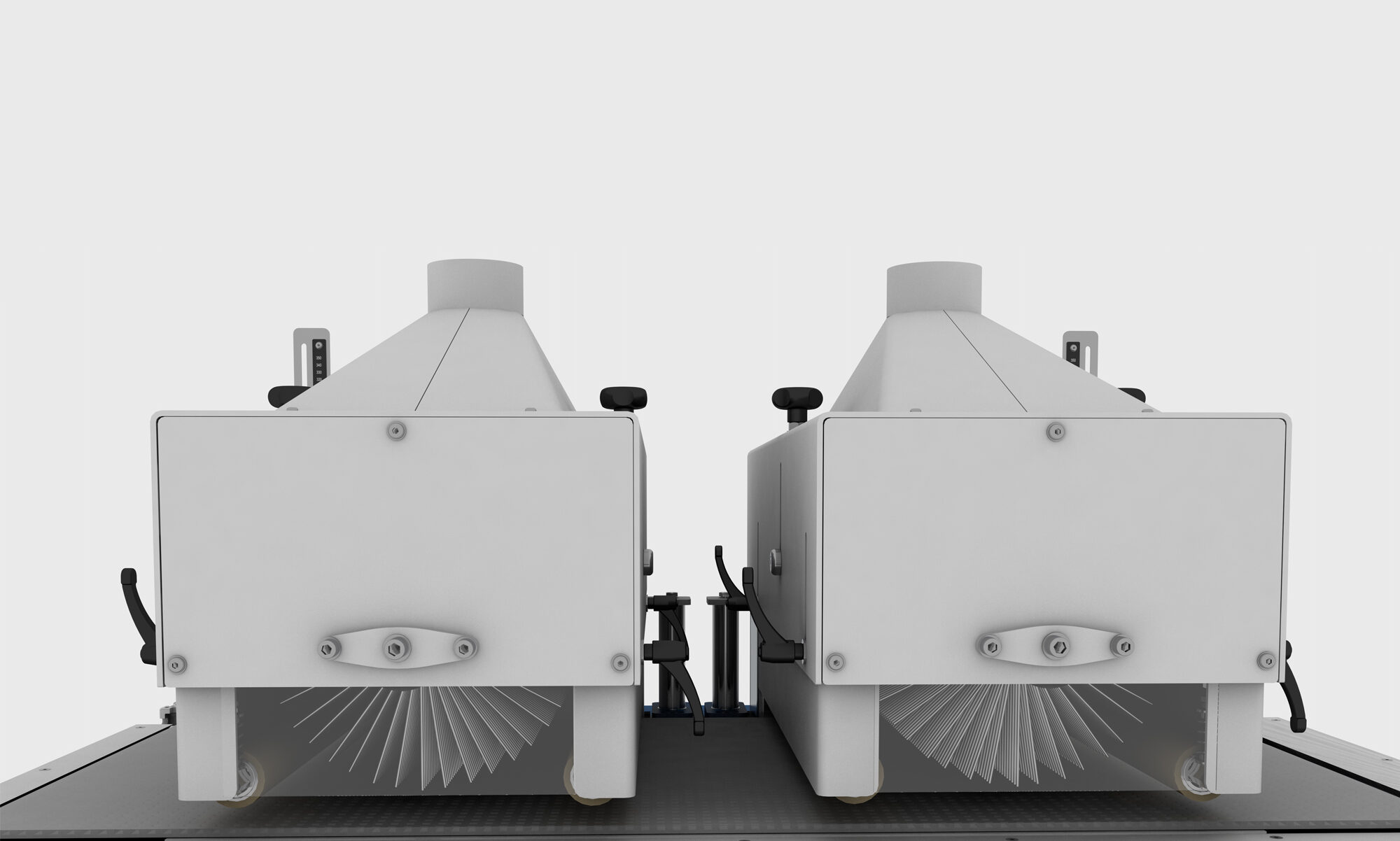

- Engine 1×4 kW (5.5 HP) – for each unit B

- Rotating diameter of the working tool 120 – 300 mm , working length 600 mm

- Independent height adjustment of work units 0-300 mm

- Fixed table h=900 mm

- Clamping shaft diameter 40 mmn

- Two height-adjustable rubberized pressure rollers per work unit

- Electric lift of work units + scale with aggregate height indicator

- Two feed belt speeds 4.5/9 – m/min

- Protective brush covers

- Diameter of exhaust outlets of units B and Q 120 mm

The Twingo makes so much sense- easy to operate, versatile and cost effective

Optional Equipment

Motors/Frequency Inverters-

• Engine 5.5 kW (7.5 HP)

• Engine 7.5 kW (10 HP)

• Frequency converter of the main motor 4 kW – for 1 unit (rpm 180-1000)

• Main motor frequency converter 5.5 kW – for 1 unit (rpm 180-1000)

• Main motor frequency converter 7.5 kW – for 1 unit (rpm 180-1000)

• Motor frequency converter for side units (rpm 180-1000)

• Frequency converter of the speed of the feeding belt 3 – 15 m/min

• Reverse operation of the main engine

Working Unit Q-

• Transverse aggregate Q – sanding belt-

– additional unit to the basic configuration of the machine – first position

– setting +/- 5°

– by electronic measurement of the working position ELGO IZ15

– pneumatic pressure shoe

– sanding belt 70×1800/2200 mm, grit P16

Side brushing unit

• Side brushing unit K1

– vertically and horizontally adjustable – manually

– table with guide and pressure

– rotating diameter of the tool 150-300 mm

• Side brushing units K2

– vertically and horizontally adjustable – manually

– min. workpiece width 50 mm (with brush diameter 240-300 mm – with support roller)

– rotating diameter of tool 2 x 150-300 mm

– working height of stand 150 mm

Other

• Oscillation of the brushing unit with the option of switching off

• Ammeter for measuring motor currents

• Electric table position measurement with digital indicator ELGO IZ15

• Automatic centering of the feed belt

• Work table extension 500 mm – entrance

• Work table extension 500 mm – output

• Vacuum table

• Vacuum cleaner with silencer

• Chassis with 4 brakeable swivel wheels