The big brother of the Buldog 3, the Buldog 5 excels in its robustness, reliability and versatility of the combination of sanding aggregates. The Buldog 5 can process material up to 1300 mm wide with solid wood, veneered surfaces and varnishes an easy task. Many thousands of these sanders have been sold across the world.

Designed for

Key Feature

Universal machine with the option of different work units Proven robust design

Standard Equipment

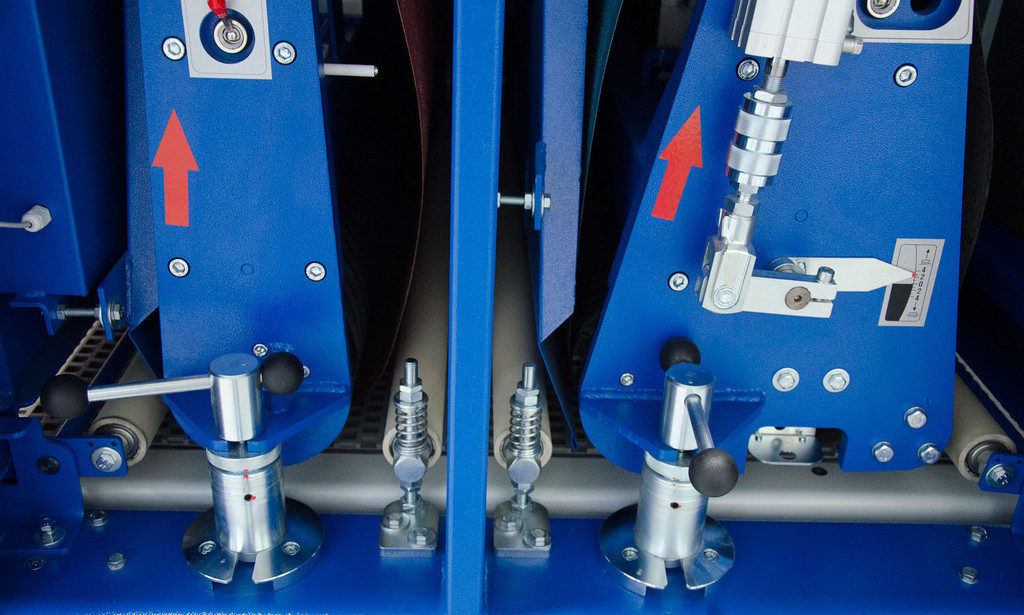

- Rubbered roller D=160 mm, 90 Sh (R, C, RR, RC, FC, RRR, RRC, FRC)

- Rubbered roller D=160 mm, 45 Sh (RR, RC, RRR, RRC, FRC)

- Milling roller (FC, FRC)

- Sanding belt width1900 mm

- Automatic rise and fall

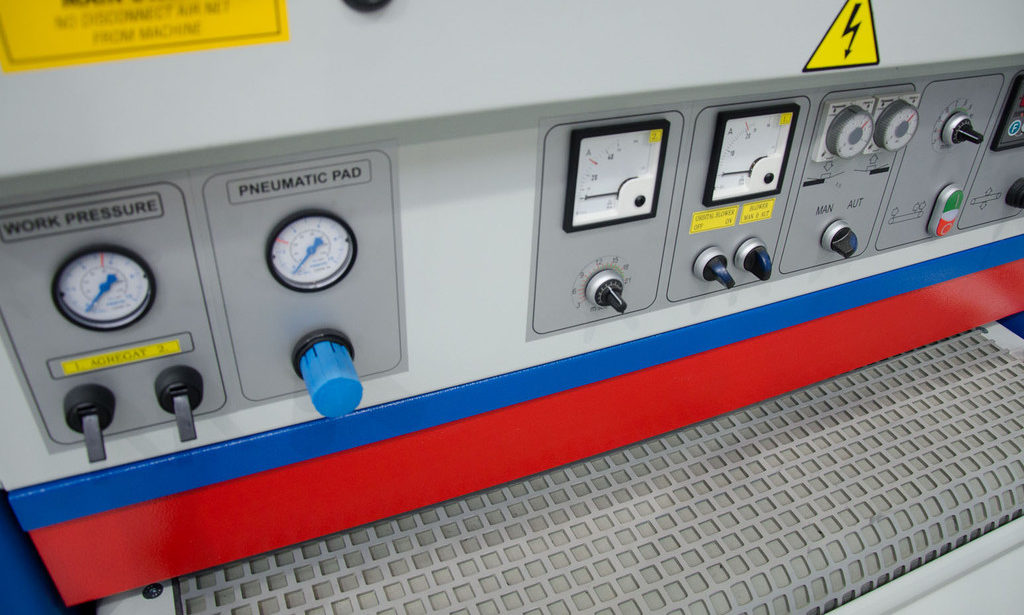

- Ammeter for measuring the motor current of Sanding unit

- Infrared sensor control of sanding belt oscillation

- mechanically adjustable base

- Automatic table height with digital readout

- operating pressure switch 3,5-4 bar

- two speeds of feeding belt 4,5/ 9 m/min

- rubber coated thrust rollers

- Main motor pneumatic disk brake

- pneumatic lift of Sanding belt for 1. Unit and mechanical lift for gr. Belt for 2. Unit

- Noise reduction features

- CE electric and safety standard

Optional Equipment

• Motor 7,5 kw (10 HP)

• Rubbered roller – diameter 160 mm, 30-45-60-90 Sh

• Operating roller steel, replacing Rubbered roller – diameter 160 mm

• Two speeds of Sanding belt 9 / 18 m/s

• Two speed motor for table lifting

• Automatic positioner of workpiece height

• Frequency converter of feeding belt speed 3-12 m/min

• Frequency converter of the main motor- belt speed 3-24 m/s

• Pneumatic time blow for cleaning 1 Sanding belt

• Pneumatic time blow with nozzle oscillation for cleaning 1 Sanding belt

• Extraction support ruler 1,2 m

• Extraction support ruler 5,2 m long

• Thrust bars for Sanding short pieces

• Limiting the maximum workpiece

• Reduction module for cleaning parts with rotating orbital blow

• Module for cleaning parts with rotating textile or nylon Brush 140 mm diameter, 1,1 kw / 1,5 HP

• Vacuum table

• Air pump 2,2 kw

• Operating pressure switch 3,5-4 bar

Machine Specifications