The Buldog 7 is engineered for high accuracy high production environments. Featuring a fixed table height and adjustable sanding heads the machine will constantly process material without variation of the working height. Available in working widths up to 1300mm and with optional segmented pads and CNC control the Buldog 7 is a leader in its class.

Designed for machining workpieces made of solid wood and composite materials made of wood, paper and some plastics.

Key Features

Powerful, comfortably equipped broadband sander with the possibility of rich accessories and assembly of various aggregates Equipped with a fixed table – suitable for the production line

Standard Equipment

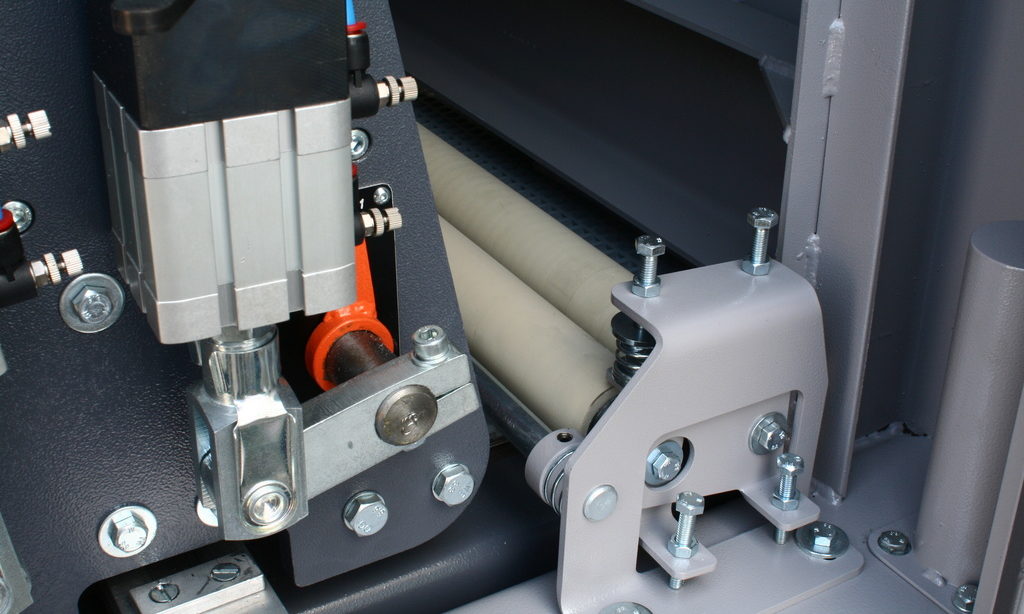

- Rubbered Roller D=160 mm, 90 Sh

- Infrared sensor control of sanding belt oscillation

- Fixed table height with powered movement to sanding heads

- Programmable adjustment of sanding head roller and/ or pad

- Electronic measuring and positioning of sanding heads with digital display

- Workpiece height positioning

- Automatic feed belt and sanding belt tracking

- Electronic calibration of sanding heads depending on abrasive belt grit size

- Workpiece thickness sensor for automatic measuring and positioning of sanding heads

- Automatic setting of operating rollers into pre-programmed positions

- 3 infeed and two outfeed pressure rollers

- Main motor pneumatic disk brake

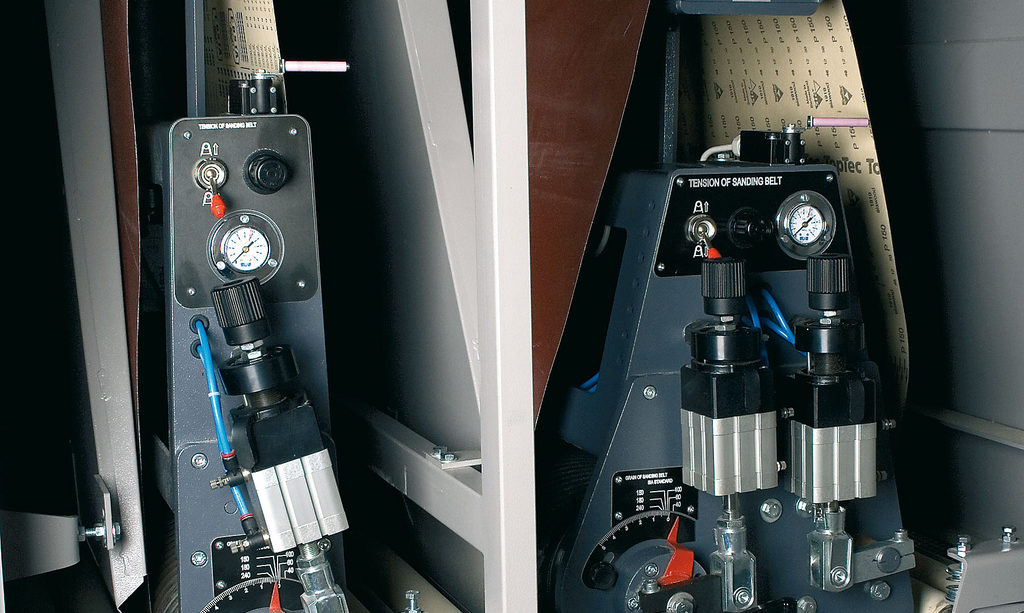

- Operating pressure switch 3,5 – 4,0 bar

- Air pressure control for belt tensioning of 2.5-5.5 bar

- Noise reduction features

- CE electric and safety standard

Optional Equipment

• motor 20 HP (15 kw), 25 HP (18,5 kw)

• Rubbered roller Ø 160 mm 30, 45, 60, 90 Sh; Ø 200 mm 30, 45, 60, 90 Sh

• Steel roller Ø 160 or 200 mm

• NC machine control colour Touchscreen 10,4″

• Two speeds of Sanding belt 9/18 m/sec – max. 11 kw

• Frequency converter of feeding belt speed 3 – 12m/min

• Frequency converter of the main motor- belt speed 3-24m/s

• Two speed motor for lifting the Sanding units

• Sanding roller with bounce and thrust

• Limiting the maximum workpiece reduction

• Thrust bars for Sanding short pieces

• Automatic workpiece positioner

• Pneumatic timing for cleaning the sanding belt

• Pneumatic time blow for cleaning the Sanding paper

• Pneumatic time blow with nozzle oscillation for cleaning Sanding belt

• Additional table – inlet

• Additional table – outlet

• Pneumatic base with bounce and thrust

• Two position pneumatic base with bounce and thrust

• Divided, pneumatically controlled base, bounce and thrust, width of segment 30 mm

• Divided, electr. Controlled base, width of segments 30 mm + NC machine control Touchscreen 10,4″

• Parts cleaning module with orbital blow

• Module for cleaning parts with rotating textile or nylon Brush diameter 140 mm 1,5 kw (2 HP)

• Vacuum table

• Air pump 4 kw

Machine Specifications