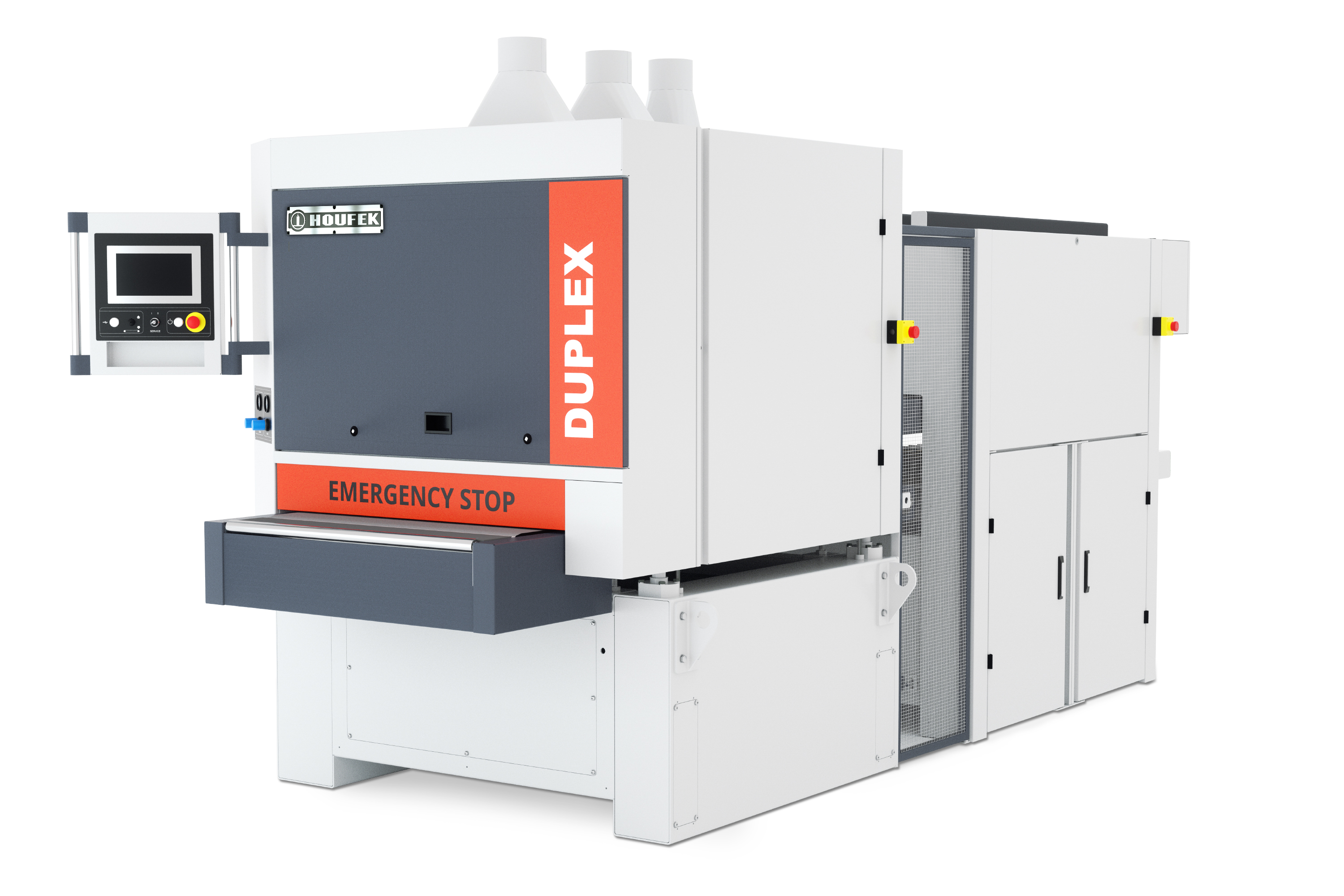

The Duplex is a powerful high-performance wide area sander for double-sided sanding up to 1300 mm. The Duplex design machine is based on the Buldog series, while the use of both sides increases work productivity. Permanent table height allows Duplex to be used in technology lines. The quality of grounded surfaces and a high degree of automation make the machine the top of its class.

Designed for sanding of wood products and composite materials made of wood, paper and some plastics in very high production environments and production lines.

Key Features

- Powerful double-sided sanding machine

- Produced in a wide range of variants

Standard Equipment

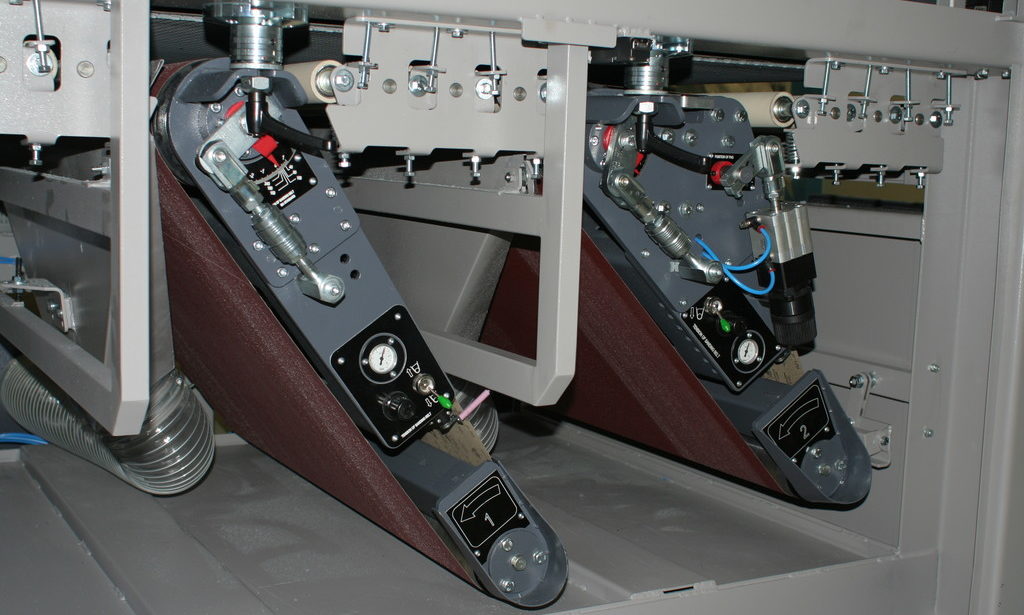

- Two sanding units of the RR-type units – the upper part and two sanding units of the RR type – the lower part

- Two sanding units: 1. type R, 2. type C + adjustable foot – upper part and two sanding units: 1. type R, 2. type C + adjustable foot – bottom part

- 1. Rubbered Roller D = 160 mm, 90 Sh

- 2nd Rubbered Roller D = 160 mm, 45 Sh

- NC-colour Touchscreen 10.1 “

- Sanding belt length 1900 mm

- Min. workpiece length 300 mm (RR-RR version)

- Minimum workpiece length 500 mm (RC-RC version)

- Infrared sensor control of sanding belt oscillation

- A solid table

- Moving sanding units

- Automatically centering the feed belt

- Automatically moving the aggregate to the specified position

- Automatic setting of working cylinders to pre-programmed positions

- Frequency converter of feed speeds 3 – 15 m / min

- Rubber pressure rollers – 2 units for each sanding unit

- Pneumatic disc brake of the main engine

- Output vacuum table

- Vacuum pump

- Operating pressure switch 3.5 – 4.0 bar

- Noise reduction features

- CE electric and safety standard

Optional Equipment

• 20 HP engine (15 kW)

• 25 HP (18.5 kW) engine

• Two sanding belt speeds of 9/18 m / s – max. 11 kW

• Two-speed engine for workpiece height adjustment

• Frequency drive speed drive 3-15 m / min (RR-RR version only)

• Main motor frequency converter – belt speed 3 – 24 m / s

• Steel cylinder replacing a rubberized cylinder D = 160 mm / D = 200 mm

• Rubber coated cylinder D = 160 mm 30, 45, 60, 90 Sh

• Rubber coated cylinder D = 200 mm 30, 45, 60, 90 Sh

• Control of the working cylinder pressure on the workpiece – controlled from the front panel

• Pneumatic timing of the abrasive belt

• Pneumatic timed blow with nozzle oscillation

• Pneumatic foot with jump and jump (for RC-RC version)

• Ionizing rod

• Pressing strips for sanding short pieces

• Limitation of maximum workpiece clearance – mechanical

• Additional table – entrance

• Additional table – output

• Module cleaning module with rotating brush D = 150 mm

• Module cleaning module by oscillation blower

• Vacuum table

• Vacuum pump with silencer

• Pneumatically operated suction flap D = 180 mm

Machine Specifications